Inventory software drives cost savings by optimizing stock levels, reducing waste, and streamlining orders to boost your bottom line. This guide explores reduce inventory costs strategies and stock management ROI, with real-world examples showing how OrderStock delivers tangible financial benefits.

Rising costs from overstock, stockouts, and inefficiencies can erode profits quickly. Inventory software counters this by automating tracking and forecasting, turning potential losses into savings. For small businesses, even modest reductions—10-20% on holding costs—can fund growth.

This article covers key savings areas, proven tactics, and examples. OrderStock, a cost-effective SaaS via subscription on tulipwork, exemplifies how smart tools yield quick ROI.

How Inventory Software Cuts Costs

Software minimizes expenses across operations:

- Waste Reduction: Prevents spoilage via precise forecasting.

- Capital Efficiency: Frees tied-up funds from excess stock.

- Order Optimization: Avoids rush fees with timely replenishment.

- Error Minimization: Cuts losses from manual mistakes.

Studies show 15-25% average savings; OrderStock amplifies this through targeted features.

Common Cost Traps and Software Solutions

Avoid these pitfalls with tech:

- Overstocking: Ties up cash—use forecasting to right-size.

- Stockouts: Lost sales—threshold alerts prevent them.

- Supplier Inefficiencies: High fees—consolidate for better terms.

- Audit Overheads: Manual counts waste time—snapshots automate.

OrderStock tackles these head-on.

Strategies for Maximizing ROI with Inventory Software

Apply these for fast returns.

1. Automate Forecasting to Slash Waste

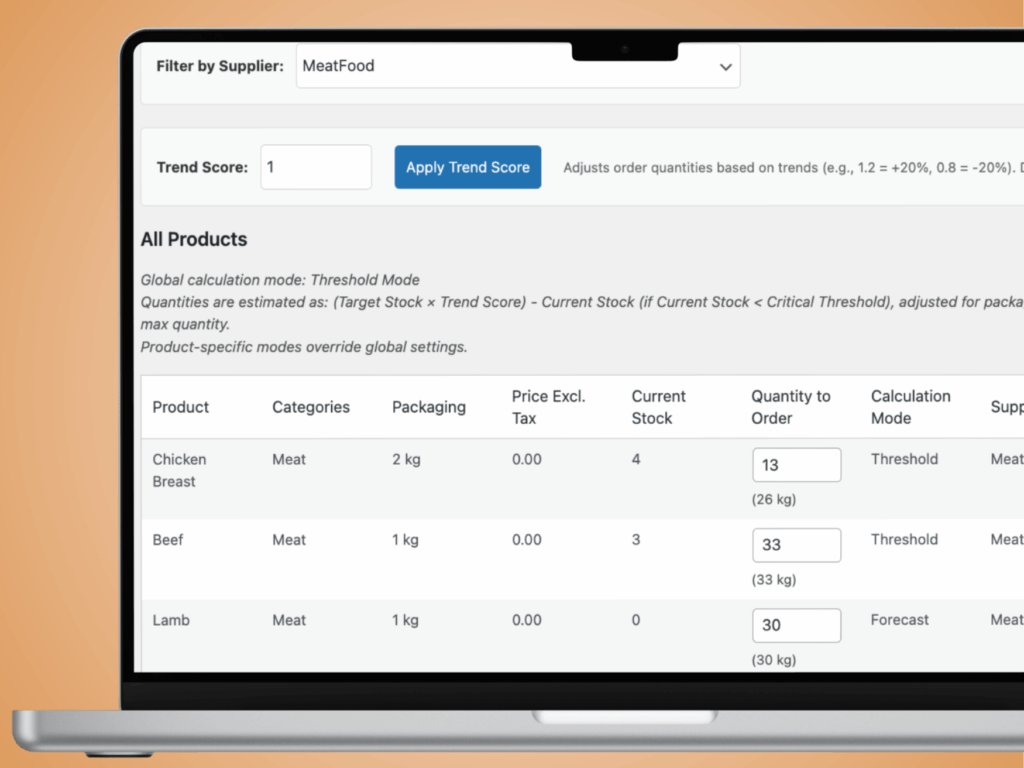

Predict needs accurately to buy just enough.

- Tip: Use sales data for trend-adjusted orders.

- How OrderStock Helps: Smart Order Suggestions in Forecast Mode calculate quantities, capping overbuys—users report 20% less waste.

2. Track Real Costs for Smarter Sourcing

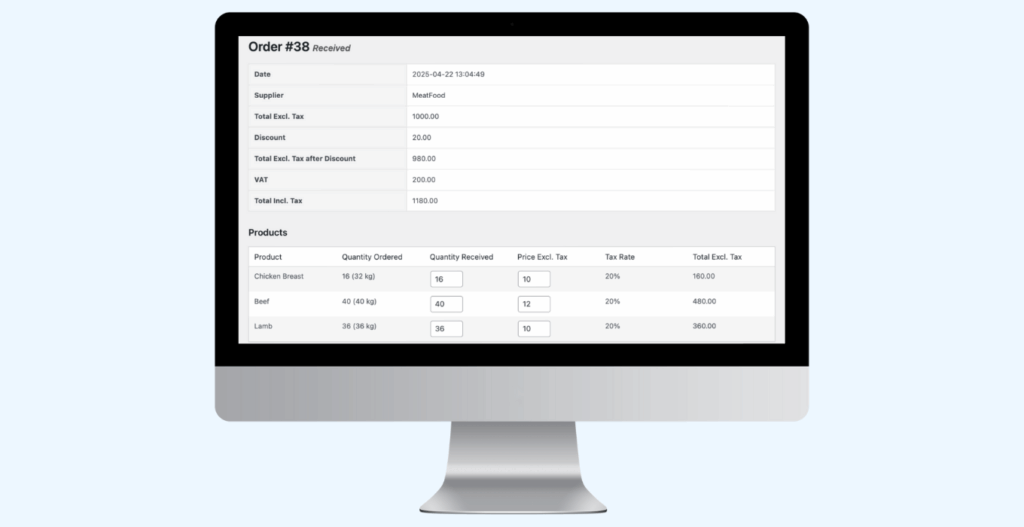

Monitor variances to negotiate better.

- Tip: Log receptions against orders for true expenses.

- How OrderStock Helps: Order History & Reception captures actual costs, feeding Insightful Reports for supplier comparisons—saving 10-15% on purchases.

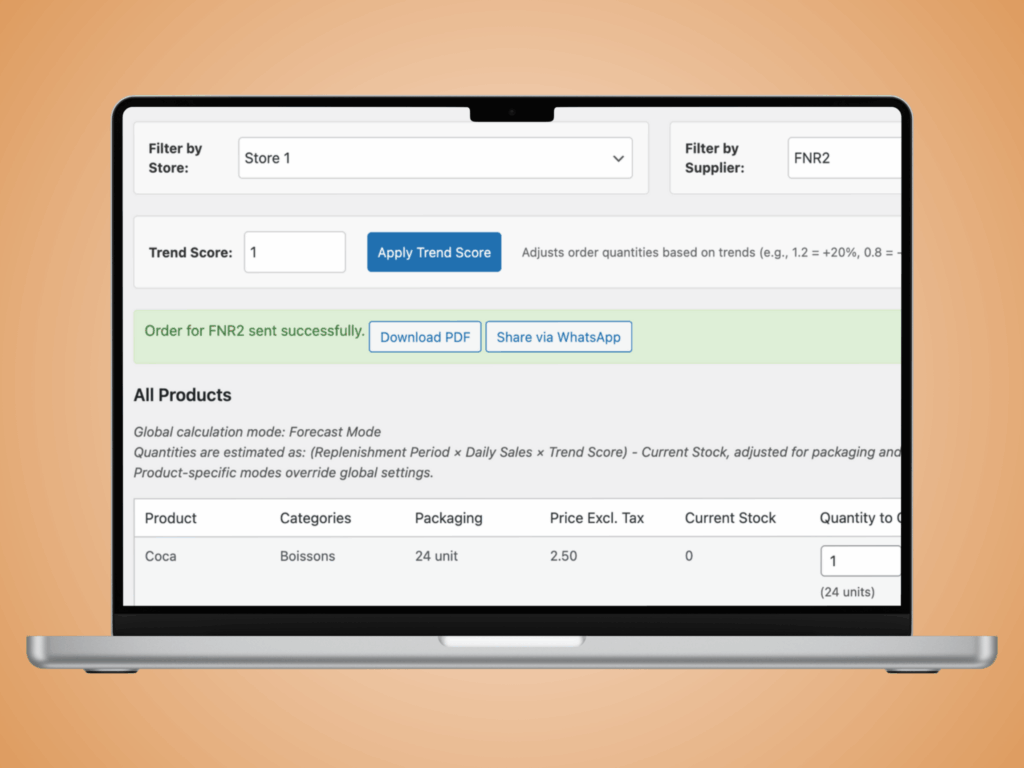

3. Centralize Multi-Store Tracking

Unify locations to avoid duplicates.

- Tip: Assign stock per site for balanced distribution.

- How OrderStock Helps: Multi-Store Mastery centralizes views, reducing excess by 15% via consolidated orders.

4. Bulk Edit for Efficiency Gains

Update en masse to cut admin time.

- Tip: Assign suppliers/taxes in batches.

- How OrderStock Helps: Bulk Editing Power saves hours weekly, equating to $5K+ annual labor savings for mid-sized ops.

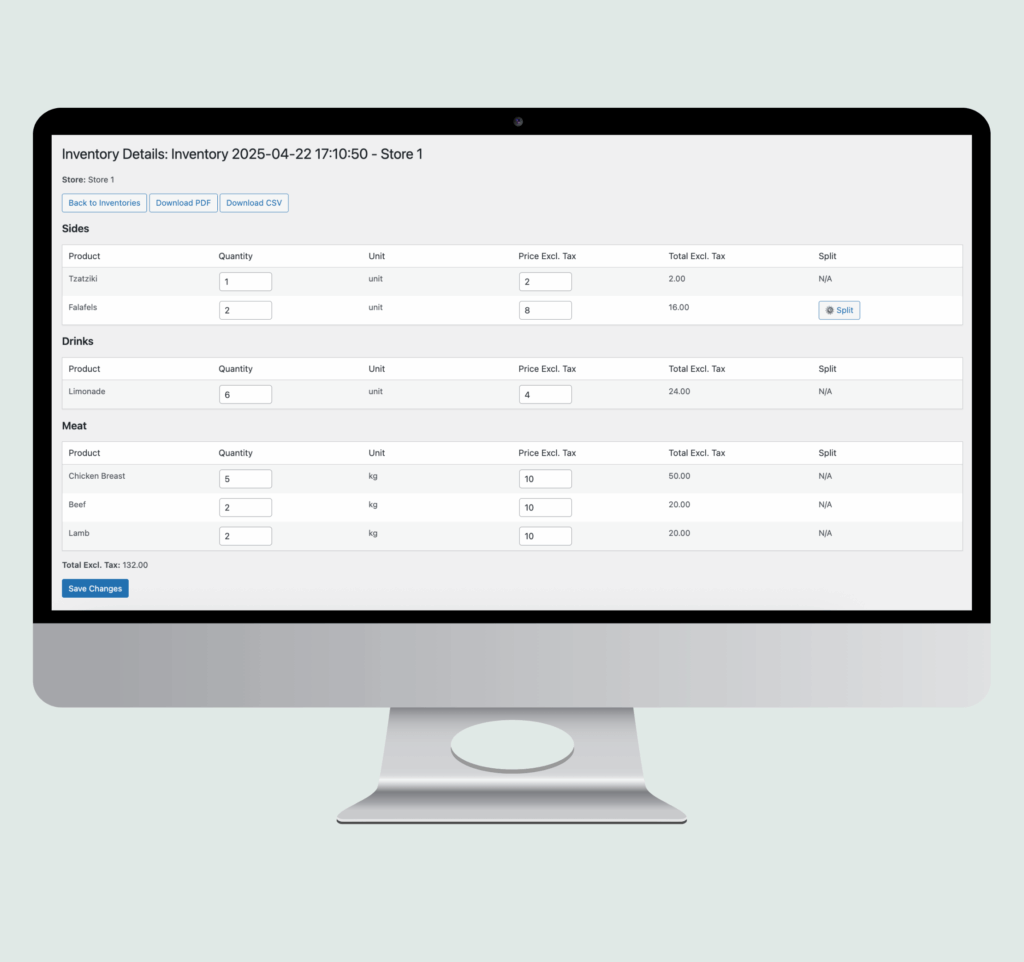

5. Generate Snapshots for Audit Savings

Capture states quickly for compliance.

- Tip: Export for reviews without full counts.

- How OrderStock Helps: Inventory Snapshots provide PDF/CSV exports, slashing audit costs by 30%.

Real-World Examples of Cost Savings

- Cafe Chain: Switched to OrderStock, cut food waste 25% ($12K/year saved) via Forecast Mode.

- Retailer: Multi-store consolidation reduced overstock 18% ($8K in freed capital).

- Caterer: WhatsApp ordering sped receptions, avoiding $3K in rush fees.

These show OrderStock’s ROI in 3-6 months.

Conclusion: Unlock Savings with Inventory Software

Inventory software like OrderStock delivers clear ROI through waste cuts and efficiency. Start saving today: subscribe on tulipwork now!