Inventory analytics empowers businesses to make data-driven decisions, uncovering trends, costs, and inefficiencies to optimize stock levels and boost profitability. This guide explores the importance of stock analytics tools and inventory reports, showing how solutions like OrderStock Pro’s reporting features transform raw data into actionable insights for better management.

In a world of fluctuating demands and tight margins, guessing at inventory needs is a recipe for waste and missed opportunities. Analytics turns overwhelming data into clear patterns, helping you forecast accurately, cut costs, and respond swiftly to changes. For small to medium businesses, where every dollar counts, leveraging these tools can mean the difference between stagnation and strategic growth.

This article delves into why analytics matter, key metrics to track, and practical ways to implement them. We’ll highlight how OrderStock Pro, a robust SaaS platform available via subscription on tulipwork, delivers insightful reports and real-time tracking to simplify optimization for any operation.

Why Inventory Analytics Are Essential for Success

Analytics go beyond basic counts—they reveal the story behind your stock. By analyzing sales trends, turnover rates, and supplier performance, you gain foresight into potential issues like slow-moving items or seasonal spikes.

Benefits include:

- Waste Reduction: Spot overstock early to free up capital.

- Demand Forecasting: Predict needs with historical data for precise ordering.

- Cost Control: Track actual expenses against budgets for better negotiations.

- Operational Efficiency: Identify bottlenecks in orders or receptions.

Without analytics, businesses rely on intuition, leading to 10-20% higher inventory costs on average. With them, you operate proactively, turning data into a competitive edge.

Common Pitfalls Without Proper Analytics

Many businesses skip analytics due to complexity, but this creates blind spots:

- Inaccurate Forecasting: Gut-feel predictions cause stockouts or excess.

- Hidden Costs: Untracked variances in received quantities inflate expenses.

- Siloed Insights: Without unified reports, trends across suppliers or periods go unnoticed.

- Missed Opportunities: Ignoring slow sellers prevents promotions or discontinuations.

- Audit Challenges: Manual snapshots make compliance and reviews tedious.

Addressing these requires accessible tools that demystify data, making analytics approachable even for non-experts.

How to Use Analytics for Inventory Optimization

Follow these steps to harness data effectively. Start small and scale with integrated tools.

1. Track Core Metrics in Real Time

Focus on essentials like stock levels, turnover, and costs to build a solid foundation.

- Tip: Monitor daily sales against inventory to calculate turnover (sales ÷ average stock). Use period-based views to spot weekly or monthly patterns.

- How OrderStock Helps: OrderStock Pro’s Insightful Reports provide real-time cost tracking and analytics by period, supplier, or category, giving instant visibility into your inventory health.

2. Generate Custom Reports for Deeper Insights

Tailor reports to your needs, filtering by store, product, or time frame for targeted analysis.

- Tip: Review order history for patterns in receptions, statuses, and variances. Export data for external tools if needed.

- How OrderStock Helps: OrderStock Pro’s advanced reporting tools deliver customizable insights, with filters for comprehensive views—perfect for uncovering trends without manual spreadsheets.

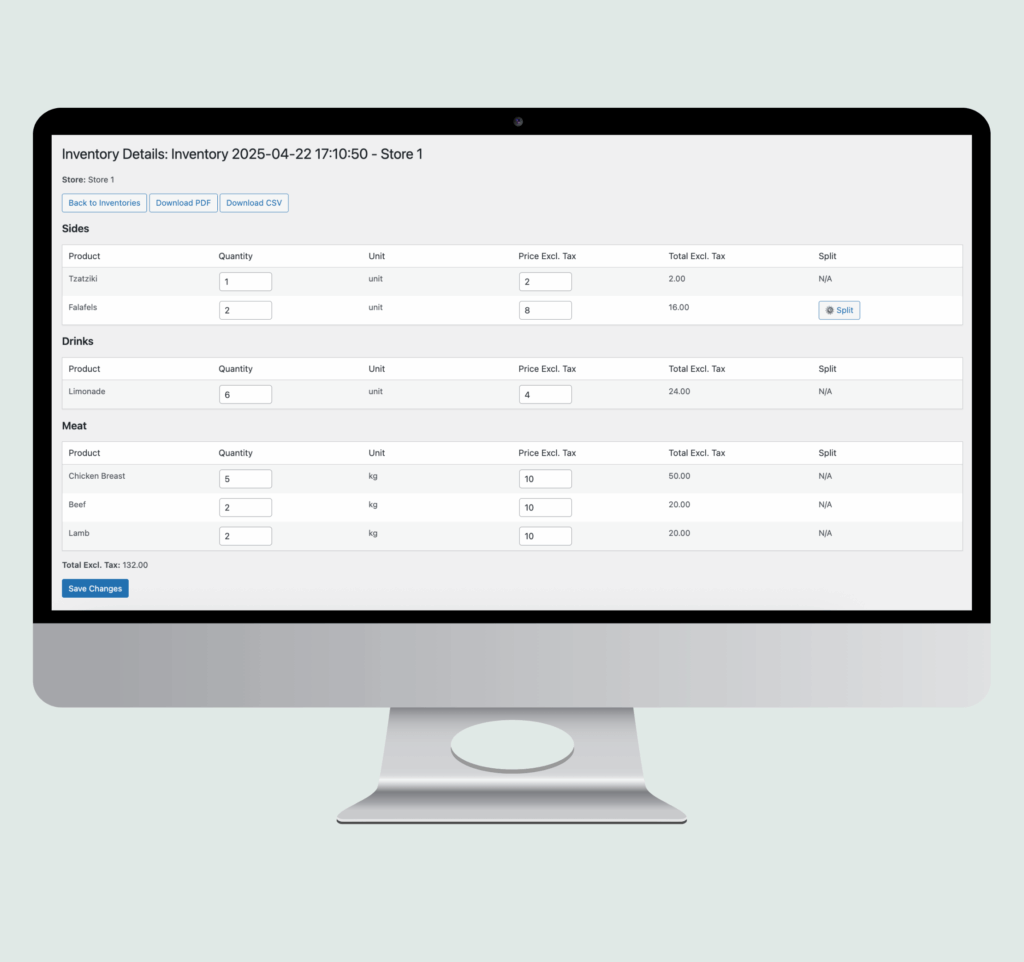

3. Capture Snapshots for Audits and Compliance

Regular freezes of your inventory state ensure accuracy during reviews.

- Tip: Schedule snapshots at month-end or before audits, including detailed breakdowns of stock values and discrepancies.

- How OrderStock Helps: Inventory Snapshots in OrderStock Pro capture stock at any moment, with PDF/CSV exports for easy sharing and detailed accounting—streamlining audits effortlessly.

4. Analyze Supplier and Cost Performance

Evaluate vendors based on delivery reliability and pricing to optimize sourcing.

- Tip: Compare actual costs against orders, tracking by supplier to negotiate better terms.

- How OrderStock Helps: OrderStock Pro’s Order History & Reception logs received quantities and actual costs, feeding into reports for supplier-specific analytics that drive smarter decisions.

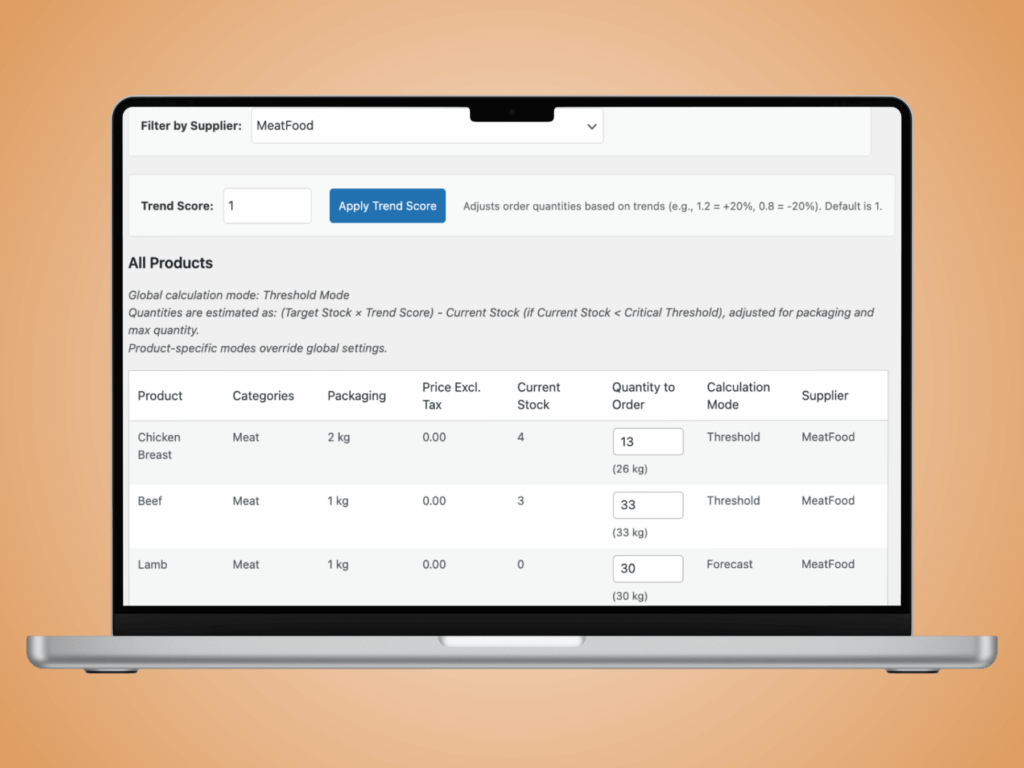

5. Integrate Forecasting with Analytics

Combine historical data with predictive modes for proactive replenishment.

- Tip: Use trend scores from past sales to adjust forecasts, aligning with threshold or period-based models.

- How OrderStock Helps: OrderStock’s Smart Order Suggestions integrate with analytics, applying Trend Scores to Forecast or Threshold Modes for data-backed order quantities.

6. Empower Teams with Accessible Data

Share insights securely to foster collaboration without overwhelming users.

- Tip: Assign role-based access to reports, focusing on relevant metrics for each team member.

- How OrderStock Helps: Team Permissions in OrderStock Pro ensure users see tailored analytics, supporting delegation while maintaining data security.

Real-World Impact of Analytics-Driven Optimization

Businesses adopting analytics see 15-30% reductions in holding costs and improved forecast accuracy by up to 25%. For growing operations, this means scalable efficiency and informed scaling decisions.

OrderStock Pro’s subscription on tulipwork makes these tools accessible, blending free basics with pro-level reporting for immediate value.

Conclusion: Harness Analytics to Optimize Your Inventory

Data isn’t just numbers—it’s the key to smarter inventory decisions that save time and money. With tools like OrderStock Pro, turning insights into action becomes straightforward, empowering your business to thrive.

Ready to optimize? Subscribe to OrderStock on tulipwork today!